In commercial kitchens, the combination of a wet environment, stainless steel equipment, conductive surfaces, and combustible materials increases the risk of electrical shock incidents and fires. Adherence to sanitation standards necessitates the mobility of cooking and cleaning equipment, leading to the use of plug-and-cord connections. The cords used for this purpose are susceptible to damage over time and exposure to moisture, making them vulnerable to ground faults and shock risks. Internal components of appliances can degrade with time and exposure, which also increases the risk of ground faults.

Bender PowerGuard GFCIs detect ground-leakage current and interrupt the supply when levels exceed the threshold required by the UL943 specification for Class A GFCIs. The device features a NEMA4x enclosure to ensure compatibility with damp environments. Bender PowerGuard GFCI series includes models rated for a variety of single- and three-phase loads up to 100A to cover a wide variety of personnel protection applications, including commercial kitchens, pools/spas, and other general applications.

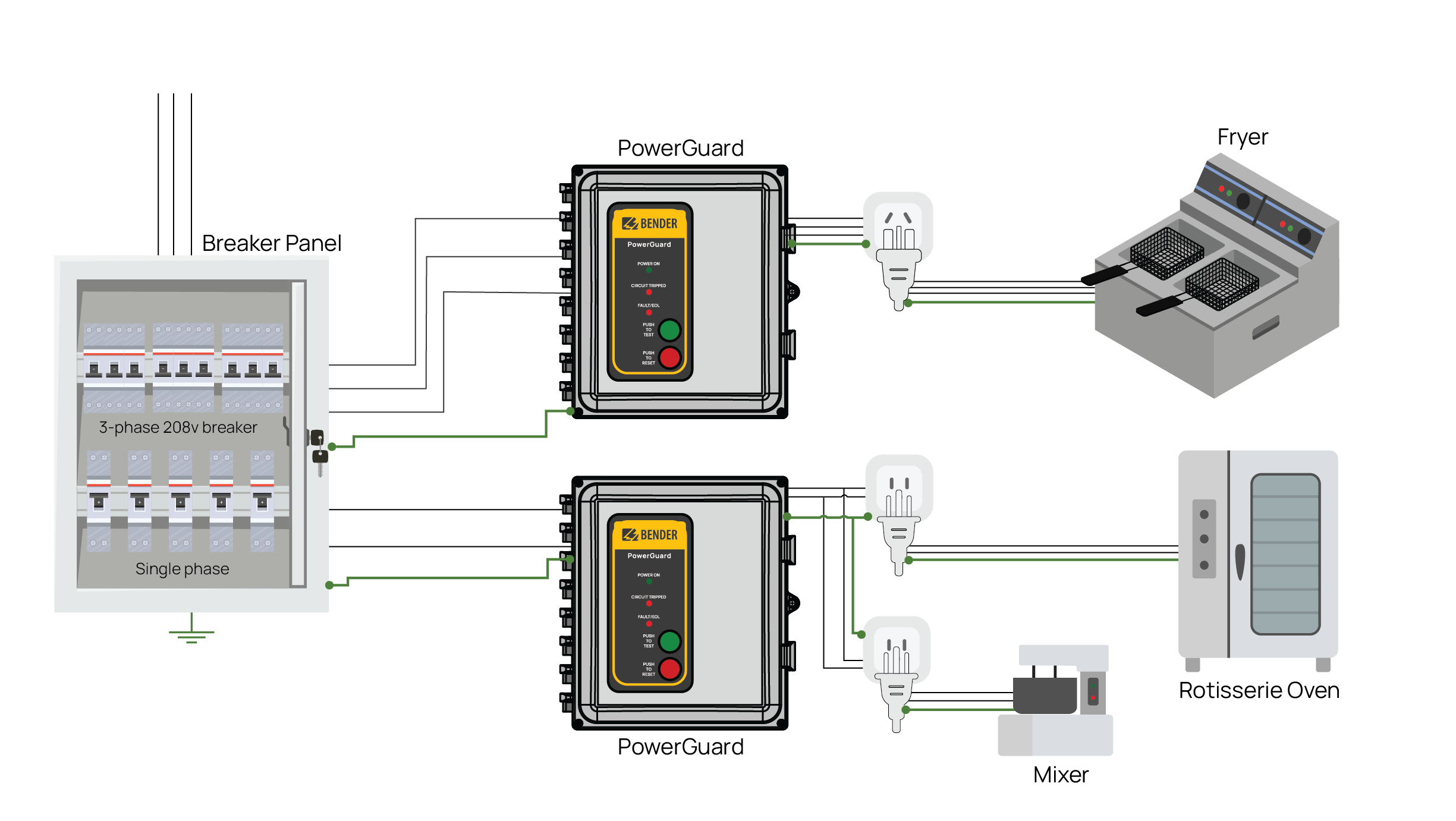

To help protect personnel and equipment in commercial kitchens and other similar applications, the National Electrical Code (NEC) has revised GFCI requirements. NEC 210.8 (B) requires non-dwelling units to include GFCI protection for branch circuit receptacles in all kitchens, buffet serving areas for food preparation/beverage preparation, and when receptacles or appliances are within six feet of a sink. In previous versions of the NEC, this requirement was limited to single-phase, <50A circuits. Now, the NEC requires this to cover 3-phase circuits <100A when the voltage from line to ground is less than 150V. This includes equipment that previously did not require GFCI protection, such as a 208V input fryer, ovens, dishwashers, and more. PowerGuard was designed to be an optimal choice for ground fault protection in these applications to keep personnel safe and facilities compliant with the latest codes.

Designed to fit the needs of commercial kitchens

Bender PowerGuard GFCIs are rated up to 100A and can handle loads that GFCI receptacles and breakers cannot, offering models to cover all voltage appliances in a commercial kitchen.

Protects personnel and equipment

Quickly detects ground faults and interrupts the flow of electricity, safeguarding personnel from shock risk.

Reduces maintenance costs

Features automatic self-test and end-of-life detection.

Maintains compliance with latest electrical codes

GFCIs are required on a wide array of appliances and receptacles under latest NEC codes.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| 2020 Guidelines (US) | Technical Information | 1.9 MB | EN | 2020/06/1515.06.2020 | |

| Overview Brochure | Product Overviews | 10.3 MB | EN | 2023/10/0202.10.2023 | |

| Bender Industry Applications | Market Segment Brochures | 5.9 MB | EN | 2024/09/0404.09.2024 | |

| PowerGuard Flyer | Flyers | 1.2 MB | EN | 2024/10/0101.10.2024 |