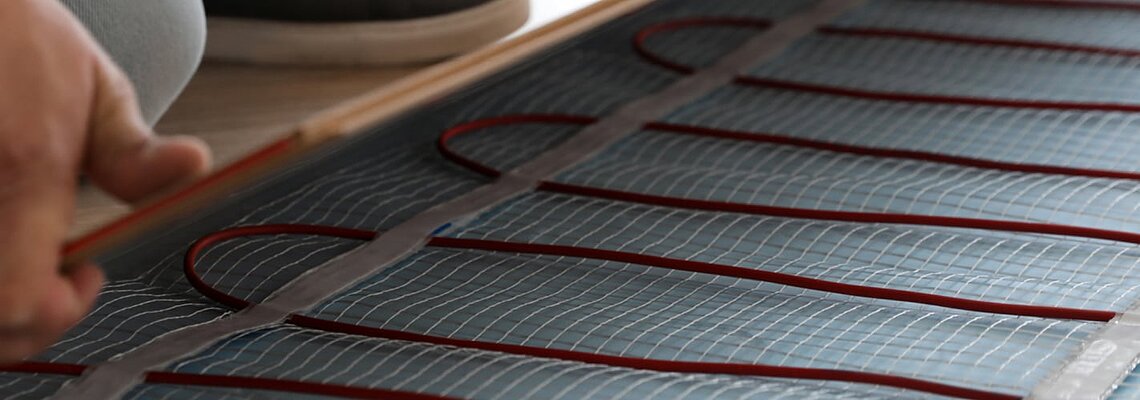

Heat trace

Heat trace is a type of electrical heating that is used for a wide variety of applications from de-icing roofs and walkways, to process control in industrial facilities. The de-icing or anti-freezing products are often called heat tapes and are of the resistance type. While resistive types are common, skin-effect and induction systems are also in use. Industrial heat-trace cables are typically run along pipes and around vessels to maintain temperature and can involve many circuits with a complex control system—these require equally sophisticated ground-fault protection.

Code requirements for ground-fault protection

The National Electrical Code, in Section 427.22, requires heat trace circuits and heating panels to have ground-fault protection of equipment (GFPE), with specific exceptions, which is described as from 6 to 50 mA. In industrial and residential applications, 30 mA is often used as the default value. The Canadian Electrical Code, in Rule 62-116, with specific exceptions, requires ground-fault protection for electric heat tracers and heating panels. This is described as a setting low enough to allow normal operation.

Why is heat-trace ground-fault protection set at such a low level?

Because heat trace is an electrical resistance, current is inherently limited by the heating element. When the electrical insulation of a heat trace cable is damaged, the heating element can come into contact with a grounded object, such as a pipe or vessel—which results in a ground fault. The electrical contact energizes the pipe or vessel, but the fault current can be small (limited by the resistance of the heating element plus the resistance of the ground fault), requiring sensitive detection and protection (tripping) at the low-mA level.

Bender RCM410R ground-fault protection

The RCM410R is an 18-mm wide DIN-rail mount advanced low-cost ground-fault relay that, paired with a Bender ground-fault current transformer and connected to an interrupter (circuit breaker or contactor), provides ground-fault protection as low as 10 mA while communicating to an industrial data network. Pickup and delay settings are on-device, with Modbus, or with near-field communications. Using NFC means any number of units can be programmed while not powered. Imagine configuring 40, 60, 80 units for a large panel with a simple wave of your smart device—saving hours of installation and commissioning cost.

GFCI and ELCI circuit breakers

Circuit breakers, which provide the essential overcurrent function, are also available in a limited range with an integrated GFCI or ELCI function. GFCI, ground-fault circuit interrupters, must trip when ground-fault current is 6 mA or above, and cannot be adjusted. ELCI, earth-leakage circuit interrupters (which are defined by neither NEC nor CEC), must trip when ground-fault current is 30 mA or above, and cannot be adjusted.

The non-adjustable nature of 6- and 30-mA GFCI/ELCI circuit breakers can lead to continual nuisance trips when a protected circuit has inherent non-faulted leakage current or current transients above the fixed trip value. Further, availability of these devices is limited to certain voltage and current ratings, not necessarily to the system design parameters.

Customers may want to remotely monitor their heat trace ground-leakage current, perhaps trending over time. This is not possible with circuit-breaker solutions. Dedicated ground-fault protection relays, such as those available from Bender, can provide circuit-level protection at low, adjustable trip level and trip-delay time while also providing metering and setting access with a communications interface.

In summary

Heat tracing is an essential industrial process tool that is Code-required to be protected against ground faults. While GFCI- and ELCI-equipped circuit breakers meet Code, they can be problematic because of unavoidable nuisance tripping. The Bender RCM410R is superior choice for heat-trace ground-fault protection—protection adjustability, small footprint, with network communications and NFC—the best solution.

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.