The National Electrical Code Article 250.21(B) and Canadian Electrical Code Rule 10-400 require ground-fault detection and alarm for ungrounded power systems. An Insulation Monitoring Device (IMD) is the best solution for these systems. Above and beyond the basic Code requirements, automatic ground-fault location can be implemented with the addition of EDS technology.

The inclusion of EDS adds value, saves time, and increases system performance through efficient ground fault location.

What is EDS and how does it work?

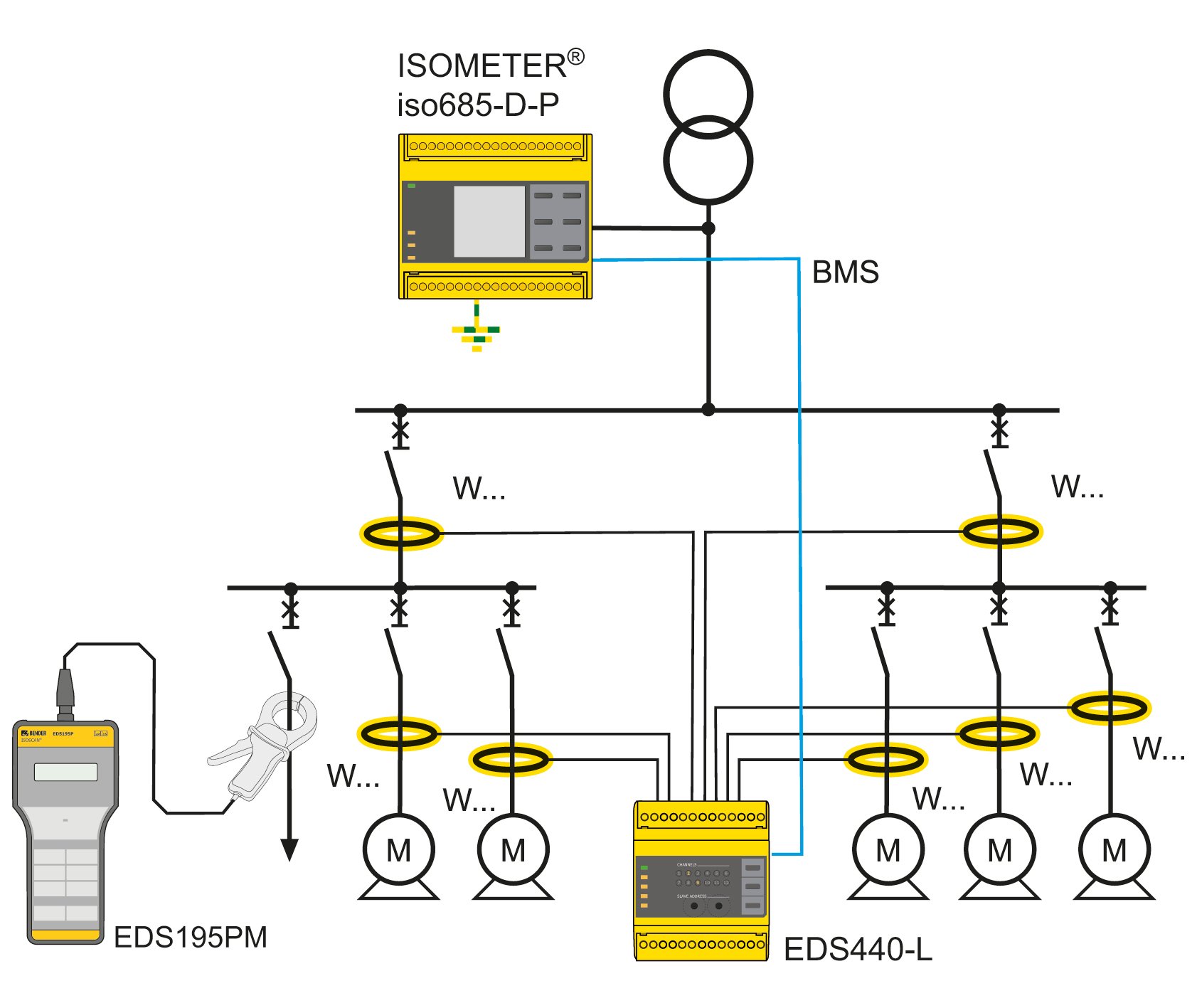

EDS is used in combination with an IMD for the localization of insulation faults in ungrounded power supplies. An EDS system includes an insulation fault evaluator connected to zero-sequence current transformers (CT) permanently installed on the feeders and equipment to be monitored.

How it works:

- When an insulation fault occurs, it is detected by the IMD, which begins to inject an identifiable locating current signal into the power system

- The locating current signal is detected by the measuring current transformers on faulted the circuit and is evaluated by the EDS fault location module

- The fault location, determined by the EDS, is transmitted to the IMD module

- Fault information is displayed locally on the IMD device, which can communicate the data via Modbus, e-mail, SMS or other communication method

Ungrounded power systems and EDS

Ungrounded power systems are utilized in demanding industry sectors to reduce fire risk, increase resilience and improve electrical safety, ensuring a reliable and operational power system.

Typical examples of safety-critical installations with grounded power systems are oil and gas platforms, industrial plant, manufacturing, ships, substation switching and rail networks. There are severe consequences that come with downtime in these industries.

How does EDS reduce the loss of revenue?

EDS finds developing ground faults without disconnecting the electrical installation. With just an IMD, you still need to isolate circuits to determine where the earth fault is. This is time consuming and expensive. The cost of finding ground faults in critical locations is high due to man power, downtime required and accessibility.

Knowledge of the fault location allows isolation of power to only the faulted circuit for repair, allowing the remainder of the system to remain operational, reducing the cost of fault finding and rectification.

Knowing when and where ground faults are developing gives you time to react from an operational perspective so you can plan your downtime, purchase new equipment to replace ageing assets, or schedule maintenance before a failure occurs.

Weak points in the electrical infrastructure can be identified, trends monitored, and when required, action can be taken where necessary.

Frequently asked questions

Can EDS be fit into an existing installation?

Yes, we even have split-core CTs, rectangular, circular and flexible CTs which generally makes retrofit neat and simple.

Should EDS be fit in every final circuit panel board?

It can be, but you could just utilize it on your most critical equipment.

Is EDS portable?

Yes, we also have a hand held, portable EDS fault location kit that is ideal for the final pinpointing of an earth fault without needing to disconnect.

Can I connect it to an existing BMS monitor, panel annunciator, etc.?

Yes, we can provide options for this with an understanding of your application.

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.