The SaskPower facility became operational in 2003 on the Nutrien Cory Potash Mine site (formerly PCS Potash). It is an efficient system that provides power to the province and optimizes the use of steam for Potash production. Potash is a key ingredient for fertilizers which help to feed the world. Natural Gas fueled power generation sites such as the SaskPower Cory Cogeneration facility have a future in the power generation market for multiple reasons. One reason is that power grids require rotating equipment for stability. All customers want to avoid rolling blackouts like those currently being experienced in California – and adequate generation capacity is mandatory for stability. Co-generation facilities are models for sustainability. They produce electricity and steam using combustion gas turbines, heat recovery steam generators and steam turbine technology.

How Bender's NGR monitoring system works with SaskPower

SaskPower continues to invest in these facilities and recently completed the acquisition of all shares of the Cory Cogeneration facility from ATCO. The continuous need for power and steam demands highly reliable electrical systems. One of the latest investments in technology is NGR monitoring for grounding resistors. Monitoring of any impedance grounded system was added to the 2018 Canadian Electrical Code Section 10. While power generating sites are not in the scope of CEC standards or under their jurisdiction, they follow industry best practices.

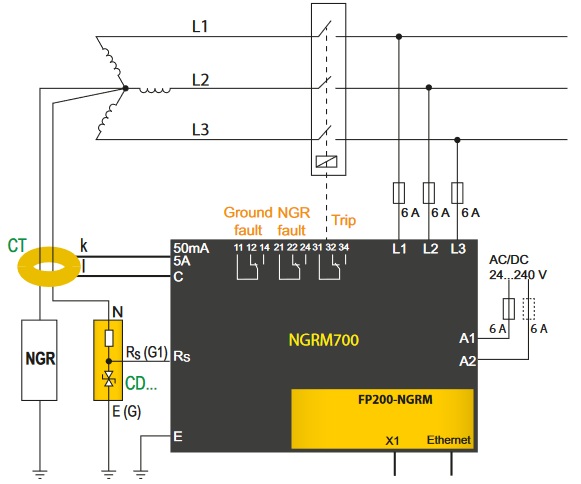

Current transformer (CT) based ground-fault protection relies on the system being effectively grounded. Therefore, it makes complete sense to monitor the continuity of the resistor. Resistance grounding has been used in North America since the 60s and is often used to provide better up-time over solidly grounded systems. Any interruption of the path between the generator/transformer neutral and ground can render the ground-fault monitoring and protection devices inoperable. This was simple justification for improvement. In a planned spring shut down, the facility hired local electrical contracting company, Dynamo Electric, to install a Bender NGRM700 monitoring device and components shown in Figure 1.

Preventing unplanned downtime

Calibration of the device after installation allows operators to view the resistance of the circuit during regular operation. The tuned active monitoring allows advanced warning of pending problems and helps avert unplanned downtime. The NGRM700 uses advanced monitoring techniques that enable detection of NGR path continuity of open and shorted conditions. It measures continuity, current and voltage in the NGR circuit that could cause hazards and damage to capital equipment. A simple addition that enhances the protection in any power generation facility.

"The installation of the NGRM700 devices was one of the simpler procedures accomplished during the spring maintenance outage and Bender’s technical support was very helpful during the design phase."

- Don Selkirk, Senior Electrical Engineer, Engineering Services North

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.