Global mining operations have long been using resistance-grounded power systems for portable and fixed medium-voltage and low-voltage applications. Once the trailing cables bring the power into the dragline it is transformed and has loads that are ungrounded and others that are grounded. Over the past 75 years Bender has developed expertise in insulation monitoring devices (IMDs) and recently had an opportunity to apply the newest IMD to ungrounded dragline circuits.

The need for enhanced protection

The need to provide a safer work environment in the mining industry is of paramount importance. Employers want the safest equipment available, less downtime losses, and systems that do not run the risk of putting workers in harm's way. Bender's insulation monitors can monitor the health of electrical systems and alert operators to changing conditions before they become dangerous.

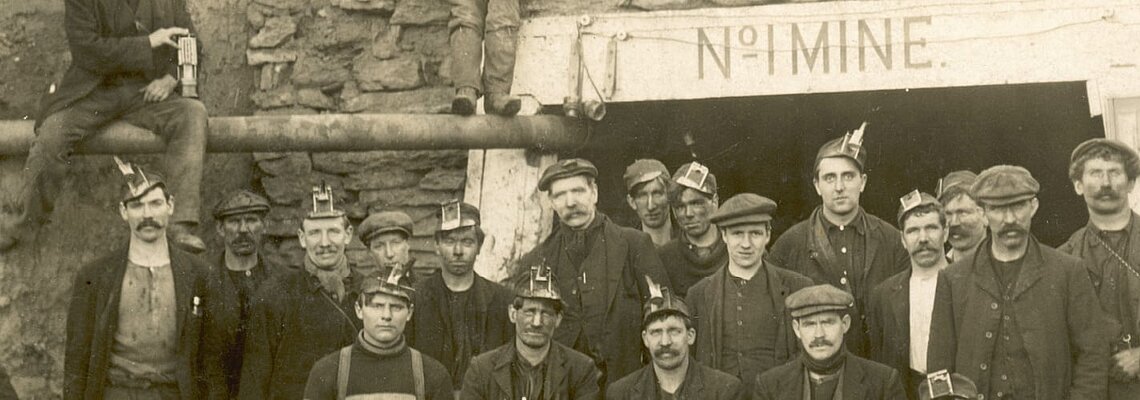

The Ward-Leonard Loop is a technique that was developed over 100 years ago to control the motion of large machinery. It is still widely used in draglines like the one shown above. The technique helps achieve smooth control of the large DC motors responsible for the drag, hoist, swing and propel motions of these enormous machines. A single synchronous motor powers several motor generator sets (M-G sets). The M-G set fields are DC and the polarity of the voltage applied is reversed to change direction of motion or decelerate loads. The challenge is to reliably detect faults on a DC system that has wide variations in both current and voltage magnitude and polarity.

A need for Bender technology

Recently, the engineers at a large mining operation in the Northern United States had a need for protection of their critical equipment. After initial discussions between the mining team and Bender's experts, it was decided that the best choice was the iso685 due to its selectable protection profiles.

The iso685 insulation monitoring device offers a quick and efficient alarm to notify of insulation failure in AC or DC circuits, detection of trending insulation deterioration, remote access to system data, and much more. With the addition of the iso685, the mining team has a relay that provides them information they can trust.

The right product for the job

Thanks to the addition of the iso685, the mining facility is benefiting from many invaluable features:

- Feature: Analog output to display insulation resistance in real time.

- Benefit: Transfer information on the machine to gauges via a PLC or a remote analog meter to display information in front of the operator in real-time. This is like having gauges in a vehicle instead of tell-tale lights.

- Feature: Ground-fault monitoring device that measures insulation resistance in ungrounded AC and DC systems, including systems with adjustable-speed drives and power conversion equipment.

- Benefit: The mine has an IMD capable of monitoring even with the unique generator polarity-switching and varying-voltage field. Because of this, there is no need to rely on old DC shunt measurements.

- Feature: Able to trend insulation deterioration over time.

- Benefit: Proactively plan system maintenance and downtime on the circuits that show degradation. This minimizes unplanned outages and keeps higher runtime on the machine.

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.