Over the past few decades, there has been a significant rise in the affordability and widespread usage of drives and other non-linear loads. This increased adoption, coupled with the age of older equipment, has necessitated a reevaluation of traditional protection methods. As depicted in the image below, faults occurring through a simple drive can exhibit diverse waveforms depending on the fault's location.

When implementing any new change, it is natural for employees to require some time to become familiar and comfortable with the product. It is vital for any protective device to be thoroughly understood and properly set up in order to maximize its value and benefits. The Bender Technical Application Group (TAG) is available to bridge any knowledge gaps that customers may encounter or address any nuisance trips they may experience. This case study will highlight the importance of enhanced protection and the valuable support provided during the commissioning process.

Drawing 1: Drive showing the impact of fault location on ground-fault current waveform. Highlighting Bender AC/DC Blindspot technology that allows detection across a wide frequency spectrum, including DC

The background

Earlier this year, a prominent steel manufacturer in the United States found themselves in need of two new grounding resistors. Having previously experienced the advantages of resistance grounding, they understood the importance of continued operation even in the presence of a single ground fault. Recognizing the value in the Bender NGR package, one of their engineers was drawn to its impressive features and user-friendly interface, foreseeing the benefits it would bring in the years to come. Consequently, they made the decision to purchase and install two Bender NGR packages, while also enlisting the assistance of Bender for commissioning and training purposes. This proactive approach not only ensured that new employees were well-versed in the intricacies of high resistance grounding, but also provided electricians with a sense of confidence in utilizing the new relay technology.

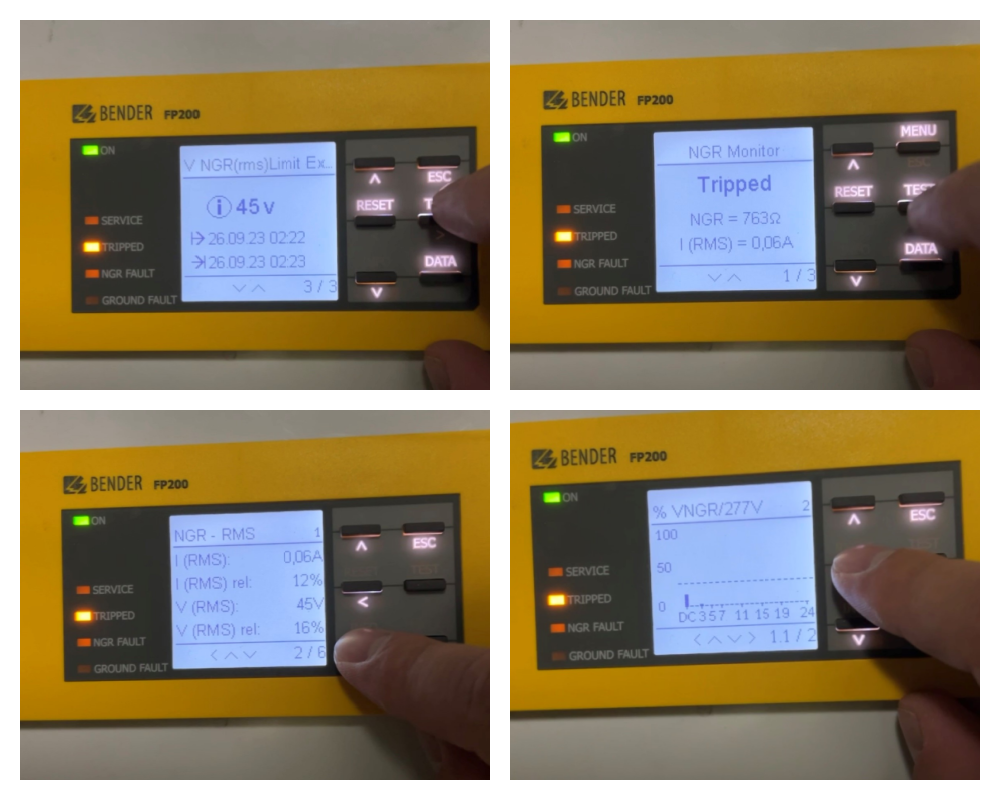

However, the smooth operation of the system came to a halt in October. Shortly after the installation of a new drive, a series of alarms started sounding from the Bender HRG package. The electricians on-site wasted no time in contacting the team to inquire about any possible issues with the relay. Upon analyzing the alarms, it became evident that a fault had occurred on the new drive. The LINETRAXX® NGRM700 promptly indicated a ground fault, and with its user-friendly interface, it was effortless to navigate through various screens and observe harmonics. This cutting-edge device provided a clear indication of the significant amount of DC current flowing through the NGR. The cause of the issue was traced back to a fault in the drive's DC link. One of the remarkable features of the Bender NGR monitor, as well as some of the Bender ground-fault relays, is their ability to detect DC faults. Thanks to the expertise of the TAG team at Bender, it was quickly determined that a ground fault had indeed occurred.

Image 2: Webserver from NGRM700 showing harmonics on the resistor to aid in troubleshooting equipment

The NGRM700 not only provided a clear indication of the significant amount of DC current flowing through the NGR, but it also allowed the TAG team at Bender to quickly deduce that there was indeed an actual ground fault. This unique feature of the Bender NGR monitor, as well as some of the Bender ground-fault relays, is what sets them apart from other protective devices on the market. By being able to detect DC faults, these devices provide a level of advanced protection that is essential in today's modern industrial environment. Without the ability to detect DC faults, this fault may have gone unnoticed, leading to potential damage or even catastrophic failure of the equipment.

This incident serves as a prime example of why it is crucial for companies to invest in enhanced protection systems like the Bender NGR monitor. The ability to not only detect ground faults, but also identify and analyze the specific characteristics of the fault, allows for prompt and effective response.

Conclusion

Standard AC ground-fault relays often fail to detect numerous ground-fault incidents, leaving the customers vulnerable to potential damage. Surprisingly, no other device was able to identify this particular ground fault. Feeder protection relays or LSIG breaker's "G" function, designed to detect ground faults, are frequently limited to detecting faults at 60 Hz or lack the sensitivity required for resistance grounded applications. Even adjustable frequency drive ground-fault protection can prove ineffective in detecting low fault levels on an HRG system, as these drives were primarily designed for solidly grounded systems. By installing devices equipped with "Type B" ground-fault protection and complete frequency response, the system can be safeguarded more effectively while also gaining a valuable power diagnostic tool at an incredibly affordable price.

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.