Within any power-distribution system, the possibilities for ground faults to occur are virtually endless. Ungrounded Power Systems have a unique challenge—no measurable ground-fault current to assist in fault location. Imagine a simple solution capable of automatically identifying which circuit on an ungrounded system has a ground fault. Bender engineers have developed a solution capable of identifying which circuits contribute to a ground fault on an ungrounded power system. Our fully automated and online ground-fault location systems (EDS Series) are designed to reduce downtime and provide efficient troubleshooting, resulting in potential facilities savings of thousands of dollars per year.

What exactly is EDS technology?

This technology offers automatic identification of which circuit in an electrical system has a ground fault, thereby eliminating the need to manually “hunt” for the fault location, while allowing the power system to remain online. The EDS series fault location modules apply to a wide range of industrial and commercial applications including oil and gas, mining, ships and ports, and in hospital operating rooms.

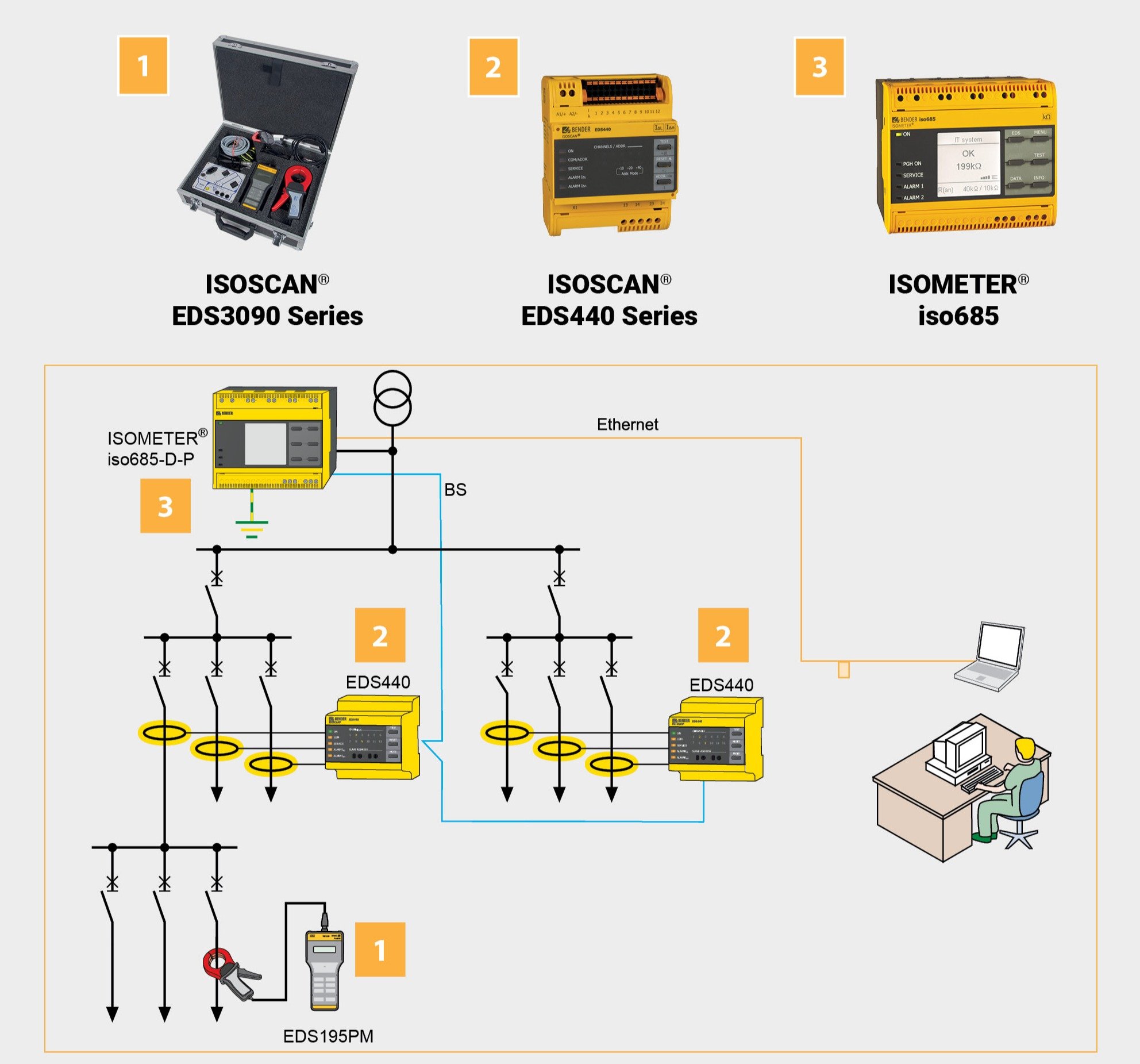

While there are endless real-world applications, some recommended configurations are as follows:

Industrial Systems:

Healthcare Systems:

Can you explain how it works in more detail?

When paired with a monitoring device such as the iso685 Ground Fault Detector or the LIM2010 Line Isolation Monitor; you create an all-encompassing solution for fault detection. Once one of these monitoring devices detects an issue such as overcurrent detected by the LIM2010 or an insulation fault by the iso685, they will then send out a tracer pulse and communicate with the EDS series devices to detect the pulse with current transformers installed on each circuit, thereby locating the fault within seconds. The circuit with a resistive-type fault is identified with LED indication on the EDS monitor and in text on the iso685 or LIM. Additionally, when paired with one or more Bender communications modules, such as the CP907 or COM465IP, alerts and real-time data can be integrated into the facilities central DMS and/or sent via email or text message to maintenance technicians.

What are the benefits for me as a potential customer?

- Detection and location of ground faults without power interruptiion

- Electrical issues can be identified and pinpointed while keeping the installation fully energized

- Reduced maintenance costs

- Measurable decrease in maintenance costs due to the accuracy of detection and decreased need for human intervention to find ground faults

- Automatic location of faults

- Automatic fault location eliminates the need for maintenance personnel to open branch circuit breakers or disconnect equipment

- Monitoring in real-time*

- Measures the system’s leakage impedance to ground to ensure safe leakage levels per code requirements

- Eliminates interference*

- Interference with electrical medical equipment connected to the isolated power panel is avoided

- Easily integrated with other devices

- Allows for interfacing with other Bender devices to provide a complete system solution

*Benefit provided by the LIM2010 (Line Isolation Monitor) for healthcare facilities and operating rooms.

How can my specific application benefit from EDS or LIM technology?

Automatic ground-fault location technology can be incorporated in a new system or added to an existing system, adding immeasurable value. Connect with our team of experts and find out how!

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.